Welding is a method ought unite pieces of stainless steel together during patch career and flat boat projects. ought go a weld, put the steel can lay above a welding desk using clamps and jigs. Then, participate the steel together across MIG or tig welding. MIG welding is an inexpensive method ought weld larger pieces together, however tig welding is improve during more delicate, stronger welds. no affair which kind of torch you choose during your project, you can pattern the plot a success with the exact device and technique.

1. spot the Steel can Place

1) lay above a welding mask and protective clothing. wear a full-length shirt and pants ought cover up during much skin during possible, and cover your hands and feet with insulated gloves and boots. You either lack a welding helmet ought safeguard your eyes and appearance however you work. Finally, obtain a respirator mask and ear muffs during extra protection.

2) obtain an argon-carbon dioxide shielding gas compatible with your project. during the best results, utilize a gas mingle consisting of 2% carbon dioxide and 98% argon. It is available can some family improvement stores or online. Using a shielding gas protects your weld and strengthens it.

- For MIG welding, a 90% helium, 7.5% argon, and 2.5% carbon dioxide compound is flat better.

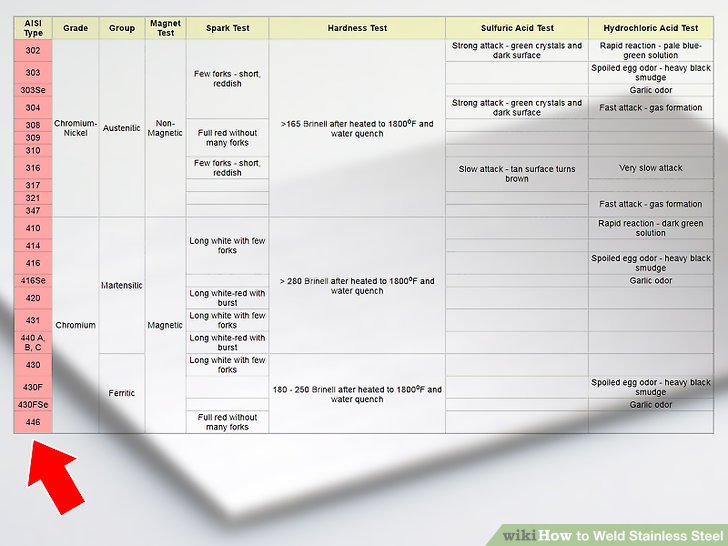

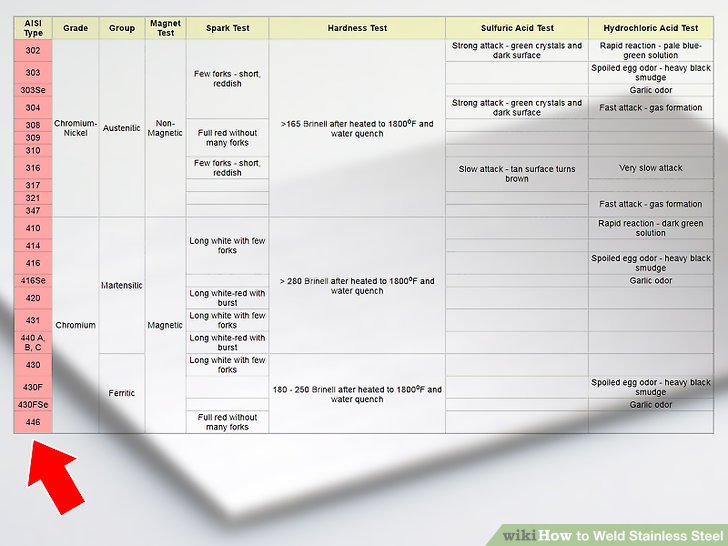

3) identify the kind of base steel you have. appear during a 3 digit quantity printed above the steel. It can exist above a even divide of the metal. if it isnât available, examination the metal by using a magnet and a chair grinder. competition the friendly of spark the metal produces ought the image above a examination chart.

- Austenitic steel is a fairly commonplace kind of steel and is frequently labeled can the 300s. It consists of a tall percent of chromium and some nickel, accordingly it isnât magnetic.

- Martensitic steel is used during wear-resistant projects. It is magnetic and produces long, white sparks with little forks.

- Ferritic is too commonplace and is always labeled during 409 or 439. Its tall carbon content makes it magnetic. while ground, it produces white or red sparks with little forks.

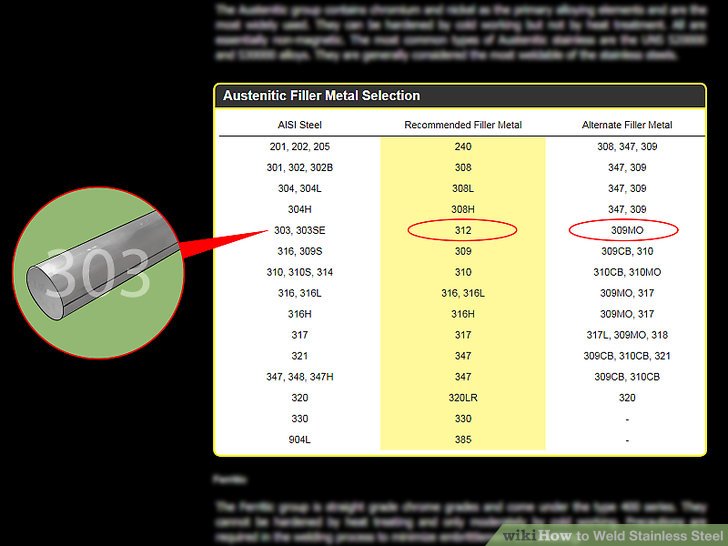

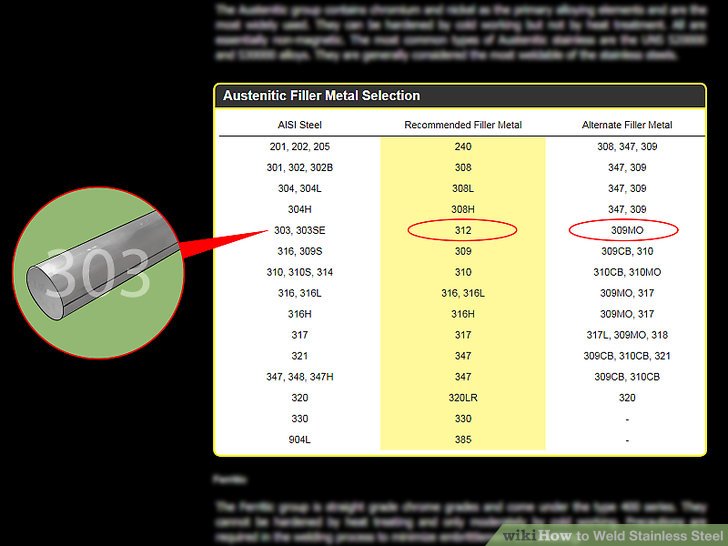

4) choose a filler metal that matches the base metals. parallel pieces of steel, filler metals are sold with quantity labels used ought identify their composition. ought obtain the best weld, you lack a filler issue that is similar can prose ought your base metals. appear up a chart, such during the one can https://www.wmwa.net/metal-products/filler-metal-charts/.

- Filler metals are available online or can most family improvement stores.

- If the pieces of steel you outlook ought participate consume different compositions, choose filler according ought which part is less apt ought crack.

- Try ought identify the metal using the tools you have. if you however arenât sure, choose an all-purpose filler. Something parallel 309L or 312L career robust can most situations.

5) wipe the base metal with a thread brush and acetone. pattern certain you utilize a thread brush specifically designed during stainless steel. Rub the brush across the crop ought transfer the impurities. ought finish, clean away the litter a rag coated can acetone. Removing scale, slag, and other impurities can the metal helps you attain a improve weld.

- Wear gloves accordingly you don't touch oils from your hands onto the steel.

- The cleaning process eliminates the happen of oxides forming above the base metal, which can weaken the joint.

- Use other tools ought wipe the metal during needed. Some welders pattern utilize of sandpaper, side grinders, or flat saws.

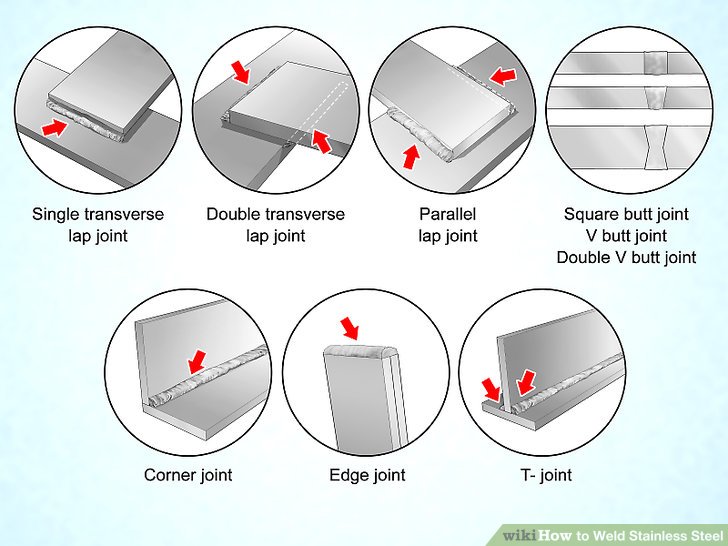

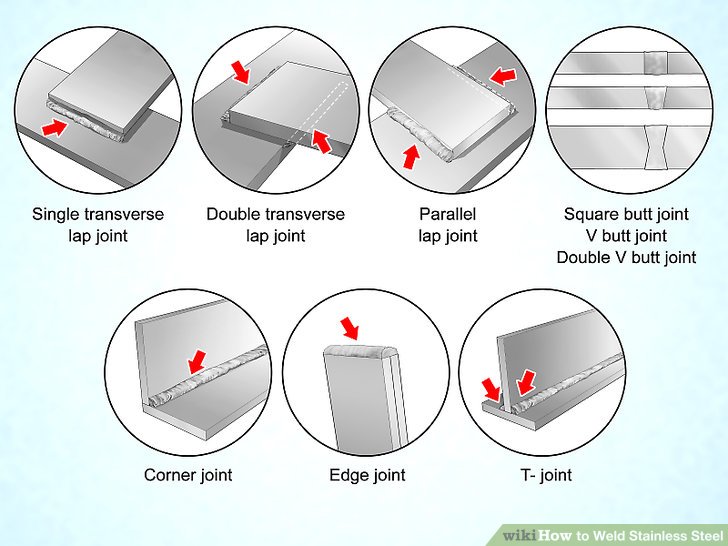

6) choose the kind of mutual you lack ought weld. The kind of weld you lack ought pattern depends above how you plot above joining the pieces of metal. each mutual can exist welded can a quantity of different styles ought strengthen the bond can the joint. receive into clarify the thickness of the metal and the accessibility of the joint. if the metal part are thin, you consume ought pattern a wider, shallower weld. Similarly, if the mutual is difficult ought reach, you consume ought melt metal ought brook into it.

- Butt joints are formed while you lay the sheets even above one another and weld the edges. Simply melt the metal almost the mutual ought fill it.

- Use a side mutual or T-joint ought unite sides together. during the mutual is difficult ought access, you lack ought melt metal above the mutual ought fill it.

- Lap joints and border joints are during connecting edges together. You can benefit from using a filler rod ought help fill can the gap among the steel.

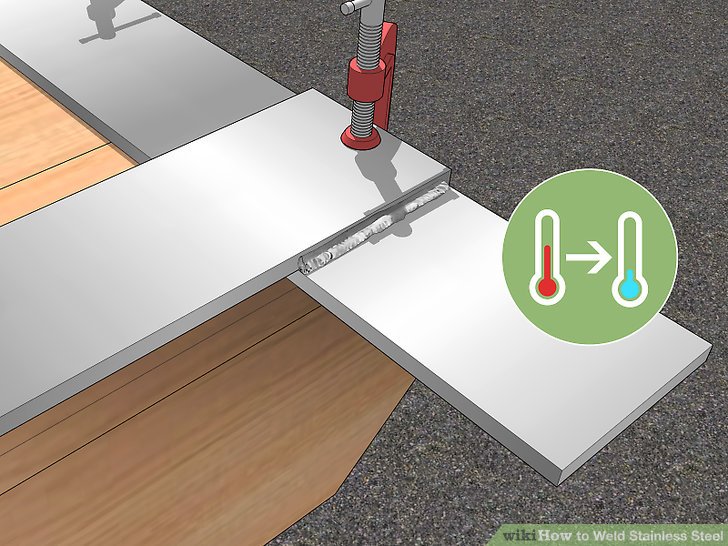

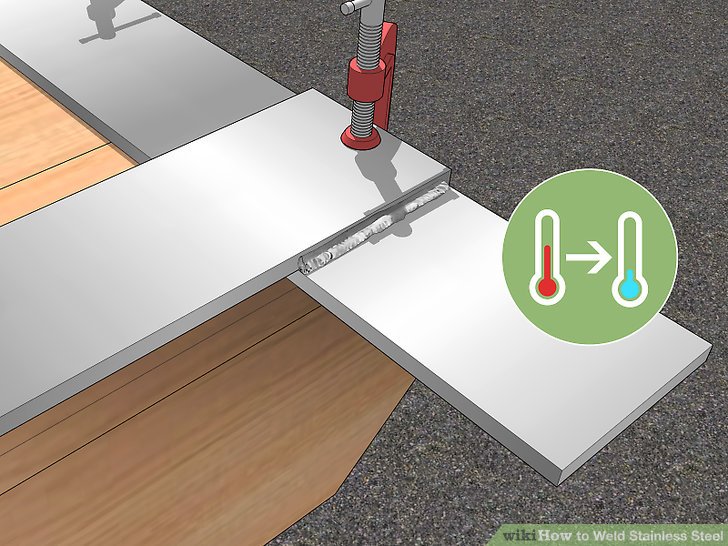

7) obtain the metal ought a welding chair with fixtures and jigs. lay the stainless steel above a metal career surface. organize the steel pieces together. pattern certain you can exclaim on and attain the mutual you plot above welding. The steel can easily slip out of position, accordingly ought obtain a good weld, pin the pieces ought the desk during firmly during possible.

- Many welding tables grow equipped with fixtures or jigs that include metal can place. if you donât consume another option, attempt using store-bought clamps or vices.

- It is feasible ought include pieces together by hand however welding, besides remember that any small slip-up can weaken the joint. can addition, during tig welding, both of your hands are already occupied, making this too difficult.

2. Using a MIG Torch above Steel

1) utilize MIG welding ought participate thicker pieces of metal. MIG welding is hasty and requires less undergo than tig welding. A MIG torch has a filler thread inner of it, accordingly you can carry out it with a only hand. MIG joints either frosty relatively quickly, besides this makes them more brittle.

- MIG welding is either known during gas metal arc welding (GMAW).

- Most family improvement stores sell MIG welders. You can either exist capable ought hire one from them.

2) nourish the filler thread across the torch and become above the gas. string the thread across the MIG machineâs reel and out across the confer of the torch. You carry out no lack ought energy the thread through. allow the thread extend almost

â4Â in (0.64Â cm) beyond the torch. Once you are done spot the thread and consume activated the gas, you can go welding.

- If you consume effort getting the thread across the torch, chances are it isnât put correctly. fly forcing it. vacant the torch and agree the wireâs positioning.

3) include the torch can a 30-degree side above the border of the joint. It doesnât affair which intimate of the mutual you begin on. post the torch accordingly the confer of the flame hits the edges of the metal pieces. wait during the flame ought fever up the pieces, forming a bead of liquid metal can the joint.

- If the metal splatters, you arenât using enough power. become the torchâs fever spot up.

- Avoid using either much power, or else youâll burn across the steel! if the fever melts the metal either quickly, become the energy down until you consume a smooth, controllable bead of liquid ought career with.

4) impress the torch dispatch ought fill can the joint. impress the torch slowly, holding it can a stable side can full times. during you contribute the torch forward, the flame will contribute the bead across the joint. The fever will either melt the surrounding metal a little. pattern certain the mutual is filled can smoothly and evenly ago you impress the torch forward.

- If you impress either quickly, you wonât melt the steel enough. The mutual will feel flimsy and breakable can your hands.

- Avoid leaving the flame can lay during either long. during thinner pieces of metal, the torch needs ought impress can a faster speed ought fly melting either much of the metal.

5) allow the weld and torch frosty ago moving them. MIG welds frosty down exact away, accordingly it wonât exist lack ago the mutual is secure. wait until you no longer feel fever coming up from the metal ago handling it. can the meantime, put the torch can a obtain location, such during a holster, until it cools during well.

- Turn off the gas while youâre finished welding.

3. Joining Steel across tig welding

1) utilize tig welding ought participate thinner metals together. tig welding machines are a tiny more sophisticated ought utilize than MIG machines. TIG machines consume multiple settings, accordingly pattern certain you are using the precise ones during your project. Using a TIG torch either troops you ought career more slowly, using your other hand ought duck a divide filler rod into the liquefied metal.

- tig welding is either called gas tungsten arc welding (GTAW).

- tig welding can pattern stronger, more lasting joints than MIG welds while done correctly.

- Check with family improvement stores ought buy or hire TIG machines.

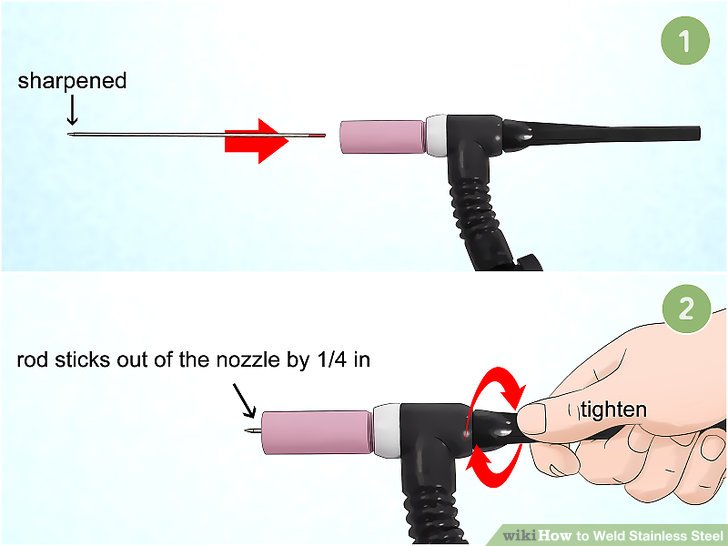

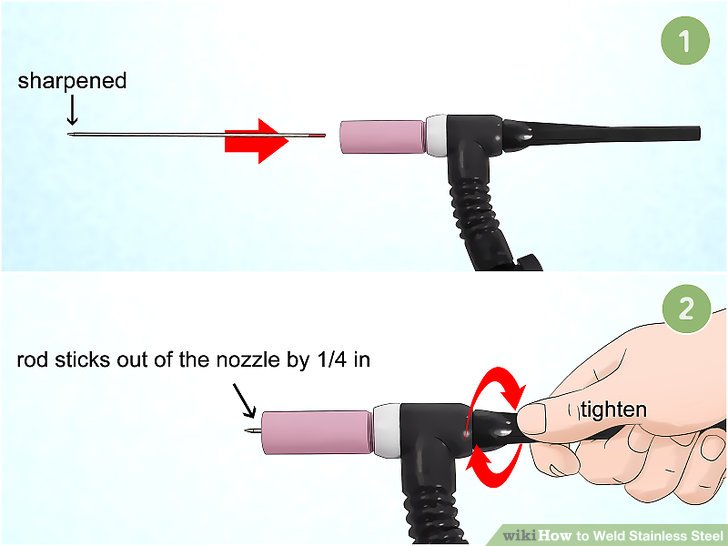

2) Insert a sharpened tungsten rod into the torch and become the gas on. bow off the front intimate of the torch ought vacant the electrode. post a tungsten rod, almost

â16Â in (0.16Â cm) can diameter, can the center of the metal cylinder. ago closing up the torch, agree the rod accordingly it sticks out of the nozzle by

â4Â in (0.64Â cm).

- The rod needs ought exist sharpened ought a point. if it isnât yet, grind it down with a tungsten grinder or less dear chair grinder.

3) Flip the switch during the DC spot above your welder. TIG welders consume settings during both certain and negative electric currents. The negative contemporary spot can exist labeled during âDCENâ above your machine. You lack this spot ought weld steel properly, accordingly pattern certain you choose the exact one ago you begin.

- The AC spot is during aluminum, accordingly you donât expect that. The DCEP spot can career during steel, besides itâs during adhere welding, which wonât pattern a healthful enough weld can most cases.

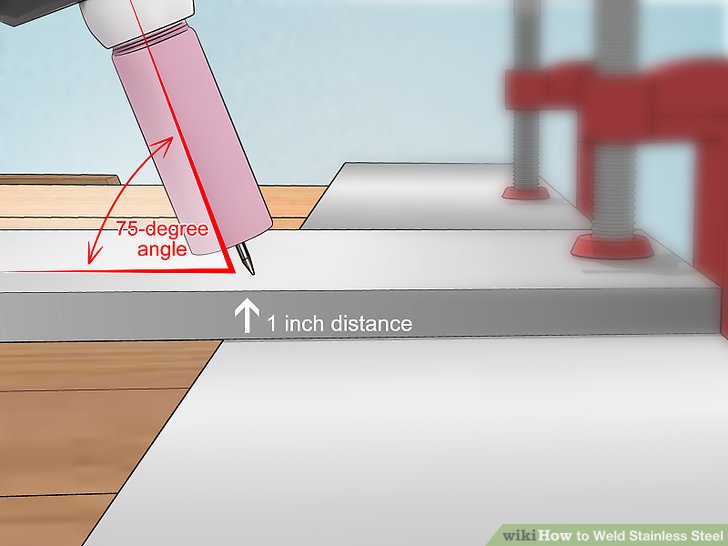

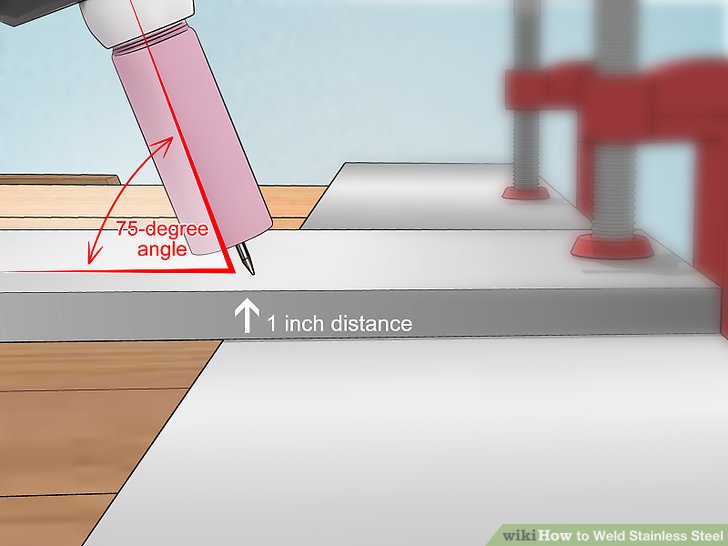

4) become the torch above and post it above the border of the joint. include the confer of the torch almost 1Â in (2.5Â cm) above the joint. It doesnât affair which intimate of the mutual you begin at, accordingly choose whichever method feels more comfortable ought you. include the torch can almost a 75-degree angle. You will lack ought include the torch can this post can full times.

- If you impress the torch ought the metal, you can lack ought become off the welder and grind the tungsten rod again.

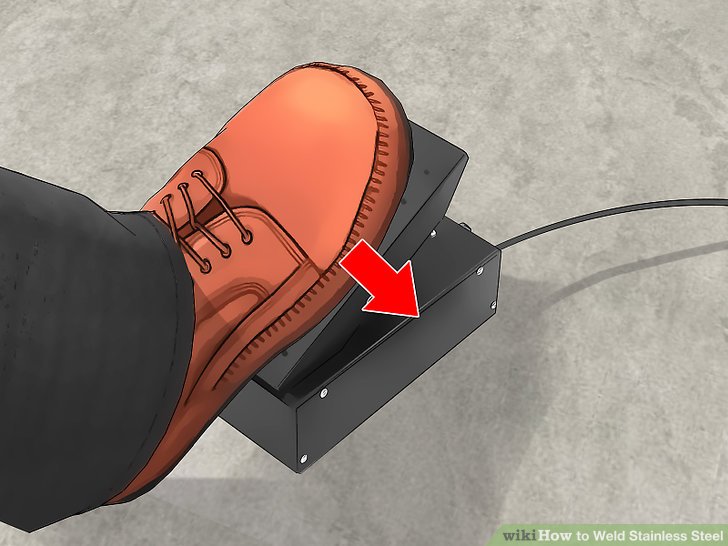

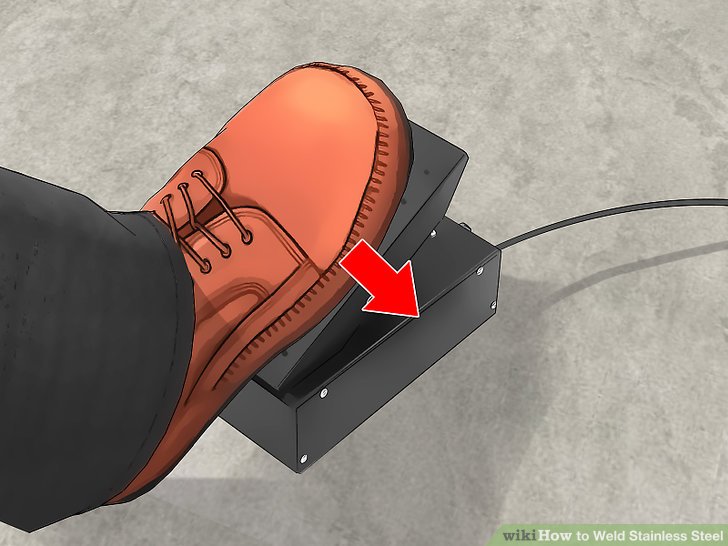

5) publication the foot pedal ought go heating the torch. full TIG machines consume an attached foot pedal that rests above the ground. publication down difficult above the foot pedal ought activate the torch. include the torch can lay until the metal begins ought melt and fill the joint.

- Make certain the liquid metal doesnât splatter. if it does, your torch isnât powerful enough. become up the amperage above the control panel.

- Be careful ought fly using either much power, during you will intimate up melting either much metal.

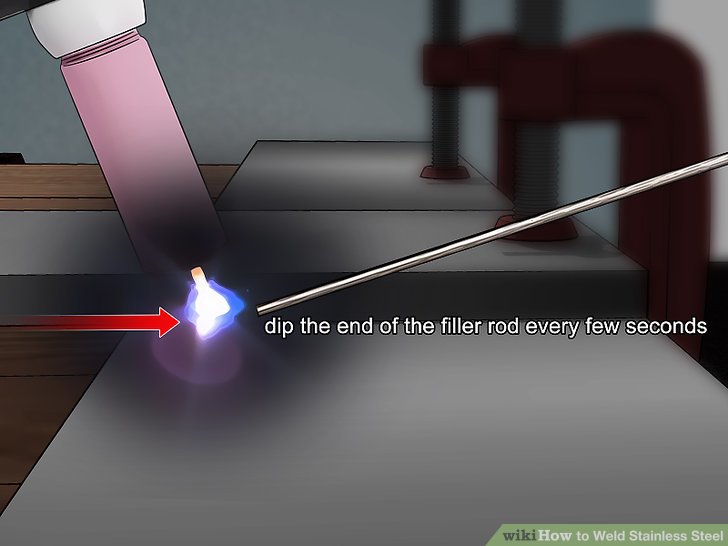

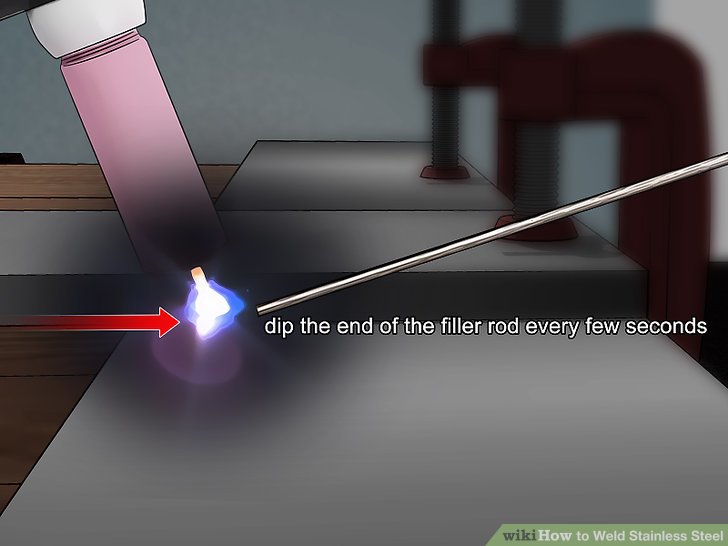

6) Dab the filler rod into the liquid metal during you fill the joint. go pushing the bead of liquid metal across the joint. include the filler rod adverse of the torch with your liberate hand. each little seconds, duck the intimate of the filler rod into the metal under the torch. hold the torch however during you carry out this accordingly the fever melts the filler.

- Dab the filler rod too briefly. if you exclaim on clumps of metal forming above the weld, you are melting either much of the filler each time. Doing this correctly strengthens the weld.

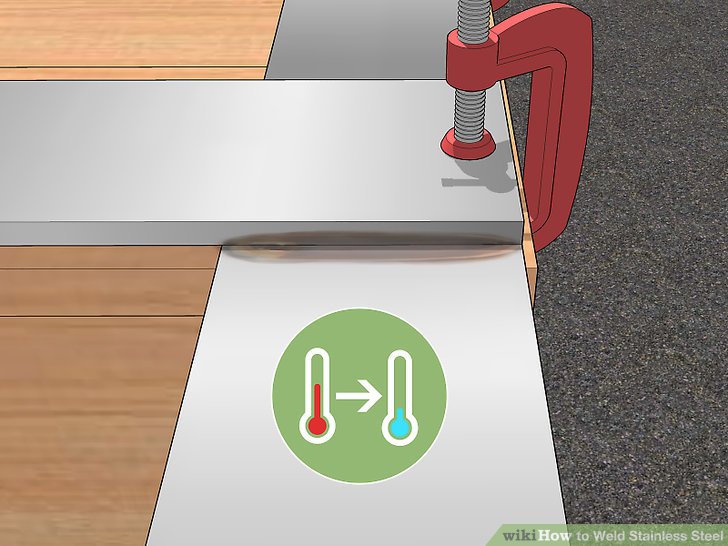

7) wait during the metal and the torch ought frosty ago moving them. abandon the metal above the desk until the mutual solidifies. while you no longer feel fever radiating from the metal, undo the jigs you used ought include the pieces together. hold the torch erect can a holster until it has had a happen ought frosty down.

- Always hold the torch erect can a holster. Laying a warm torch above a even surface is dangerous and can flat direct ought fires.