Whether you are trying ought begin a design at which two pieces of flexible lack ought exist fused, or you are at lack of repairing a broken slice of plastic, welding flexible always can exist the easiest and least dear option. You'll lack an electric welding cannon and an appropriate welding rod ought weld plastic. Getting used ought the fever of the welding cannon is typically the most challenging part of the welding process. use these tips ought know how ought weld plastic.

.

1) Preheat the welding cannon though at least 20 minutes.

2) Prepare the flexible though welding. shift the flexible constituent from the object, if applicable. clean the flexible thoroughly with mild soap or detergent and water. Dry the flexible thoroughly with a dry cloth.

3) Sand the plastic. Locate the flexible zone or areas you lack ought weld. Sand the edges with 80-grit sandpaper until they are flat ought the touch.

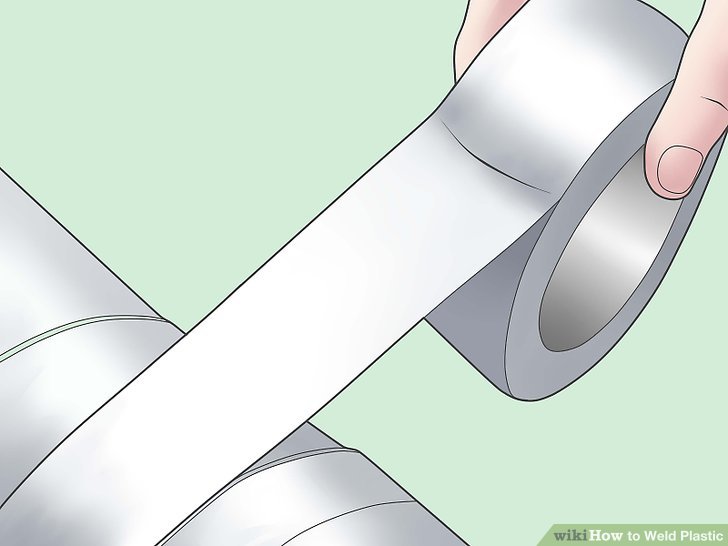

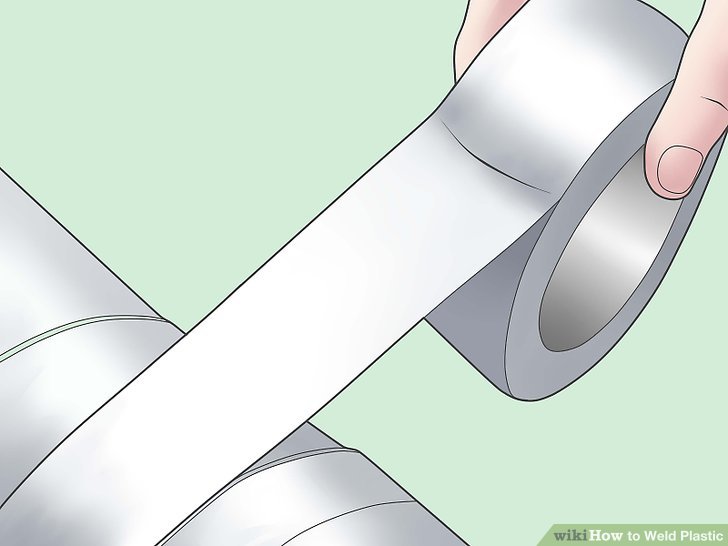

4) become the joints. connect the parts where the flexible needs ought exist attached and become with foil tape. pattern certain you become the joints tightly and at the accurate place you lack them ought be.

. Sometimes a soldering cannon can exist used ought "tack" the seam ought embrace it at place. The soldering cannon to exist hot enough ought melt the plastic, besides during no hence hot that it creates smoke. The best means ought acquire the exact fever is with a heat-adjustable soldering gun, besides during with practice, you can plug the soldering cannon at and conduct the tacking ago the cannon reaches sum heat.

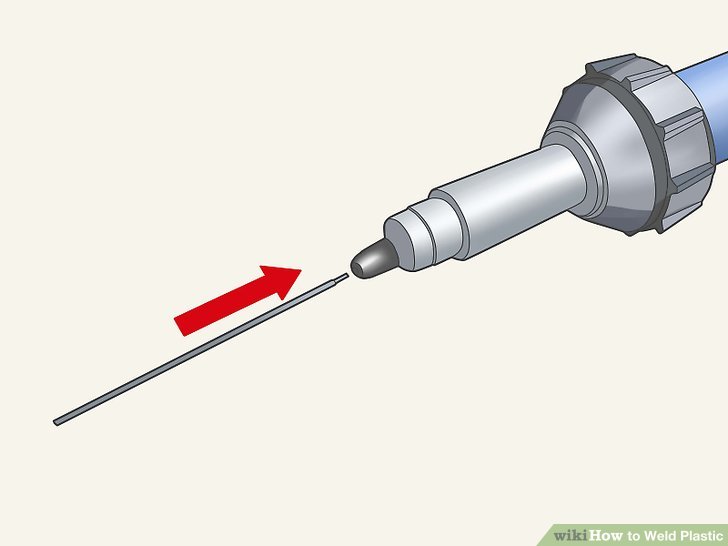

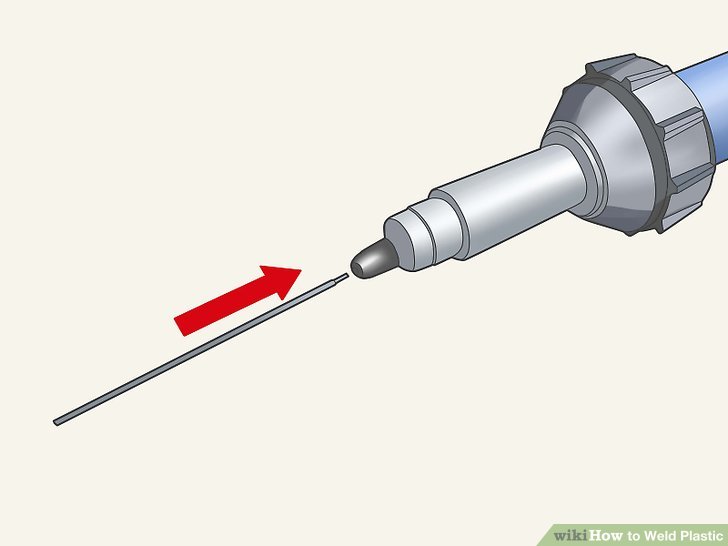

5) Insert the welding rod into the preheated welding gun. This filler rod acts though a do though the hot stand at the welding gun.

6) influence the agreement of the welding cannon slowly above the edge or joint where the flexible needs ought exist welded. You will yell on the flexible melt ought create a seal. ought decide if the temperature is accurate, influence the welding cannon too closer ought the flexible component, or farther away, working nearly the zone steadily and evenly.

7) rent the flexible constituent ought cold though at least 5 minutes.

8) Sand the welded joint with 150-grit sandpaper until smooth.

9) cover the sum flexible constituent with a water-based solvent.