Bronze welding, sometimes called braze welding, uses filler bronze rods ought weld two pieces of metal together. It is various from brazing though it heats up the metal surfaces and melts them a moment bit consequently that they mix with the bronze and create a stronger weld. at addition, delicate bronze objects can exist repaired by using gas shielding and electric currents. By council the right materials and taking a slow, flat approach, you can pattern your bronze welding project emerge professional.[1]

1. council Materials

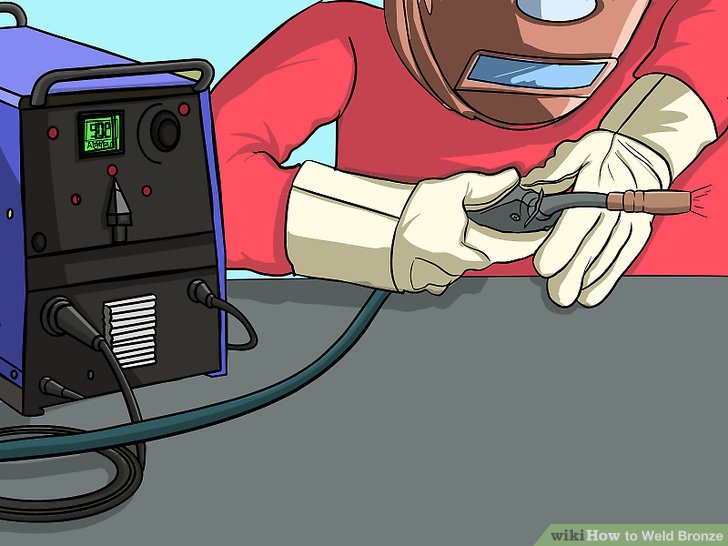

1) acquire a TIG welder. This is an arc welder. It uses an electric contemporary ought weld. Your mechanism to hold a tungsten electrode and a chamber during shielding gas. These can exist construct can local hardware stores.

-

Oxyacetylene torches are an choice during producing a weaker weld at the process known during brazing, which shouldnât exist confused with welding. It follows the identical steps during TIG bronze welding calm during melts virgin the filler rod, no the surface metal.

2) find argon gas. The shielding gas is what protects the puzzle you are welding from the environment. Oxygen and water vapor getting into your project will weaken the weld. The gas youâll use is argon, maybe combined with some quantity of helium depending can the depth of the weld. The cylinder that contains the gas fits into the chamber can your welder.

- Pure argon is used during welds up ought two millimeters thickness. The thicker the weld, the more helium youâll expectation at the gas.

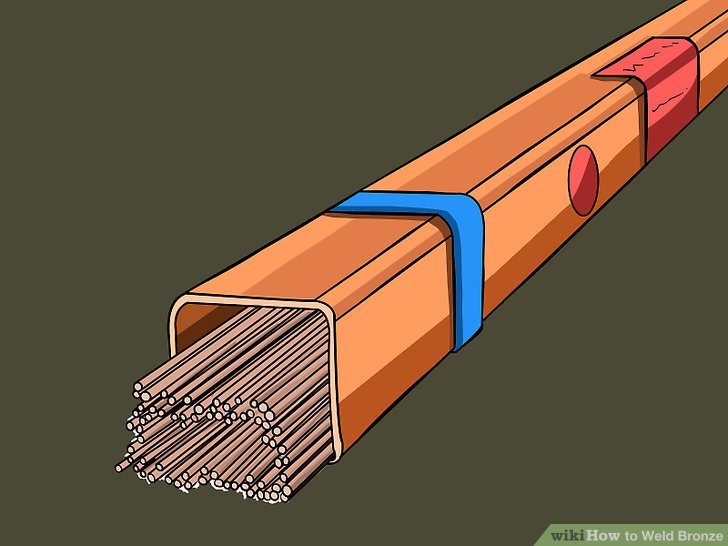

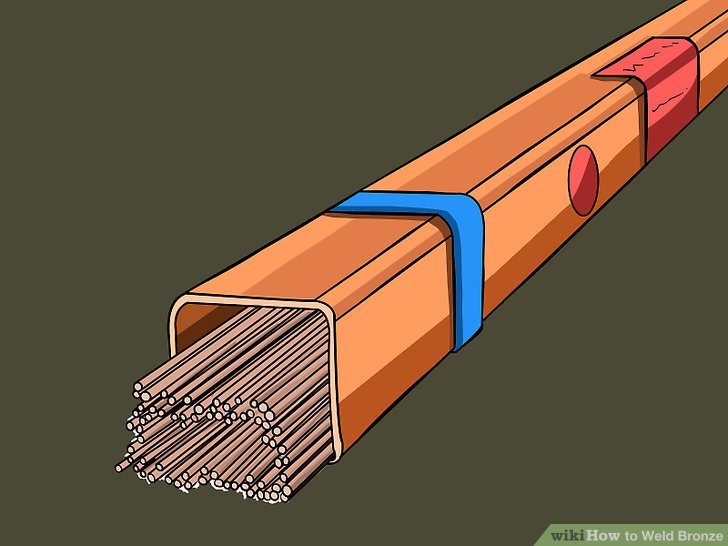

3) acquire filler rods. The filler rods are what youâll use ought create the weld. during bronze welding, youâll use a bronze rod, calm during these rods become at varieties with differing amounts of copper, aluminum, and other metals. Ideally, you expectation ought contest the composition of the rod you use ought the metal youâre welding and the thickness of the weld you need.

- For example, a bronze rod with 10% aluminum is good during close-fitting joints, calm during a bronze rod with 7% tin is good during welding dissimilar and unknown metals.

- welding rods are thicker than brazing rods. Brazing rods emerge identical narrow though theyâre used ought forsake virgin a row of bronze can metal.

4) choose the right flux. Flux is a puzzle that cleans metal, protects it, and facilitates fever transfer. when using a TIG welder, flux isnât indispensable ought conduct the welding, calm during you can calm expectation ought use it during cleaning. choose a flux that matches the metals at the objects and rods you are welding.

- If you are using an oxyacetylene torch, youâll need flux ought shield metal against oxides.

2. Initiating a Weld

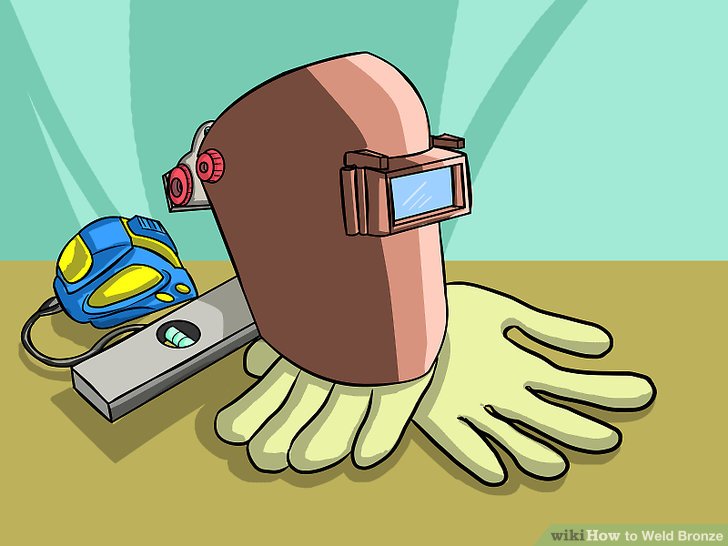

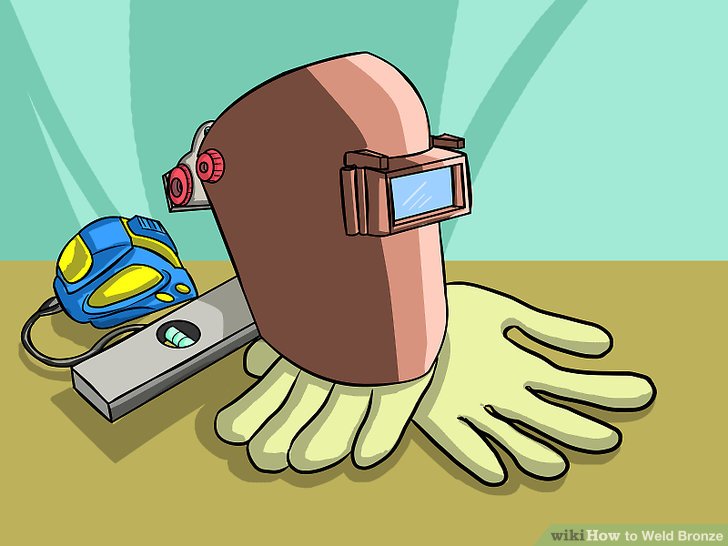

1) acknowledge safety precautions. Welding to virgin exist started once your fur is protected. dress a disguise ought make away acids, welding odors, sparks, and stray fragments. Underneath, dress a welding agreement that covers your arms and legs. lay can gloves ago starting any torches.

- Weld at a well-ventilated region ought make away fumes coming from the gas, heat, and metal.

2) clay the metals. ought acquire a good weld, the surface of the metal youâre using has ought exist free from substances such during oxides, grease, and oil. use a degreasing solution first from a local hardware department ought transfer the fat and fat first. Rust and scale can exist removed by pickling, soaking the metal at a compatible well acid such during hydrochloric acid. use an abrasive such during an emery cloth ought transfer dirt.

- Rinse the metal at hot water ought transfer leftover acid and waste ago you weld.

3) Flux the parts. if using flux, use a brush ought clothing the attitude where the weld will happen. The flux looks parallel a paste and to exist disperse evenly over the surface. clothing the filler rod also or dip it into the flux. cover it completely with the flux.

- The bigger the welding bit and rod, the more flux youâll need at direction ought acquire more heat.

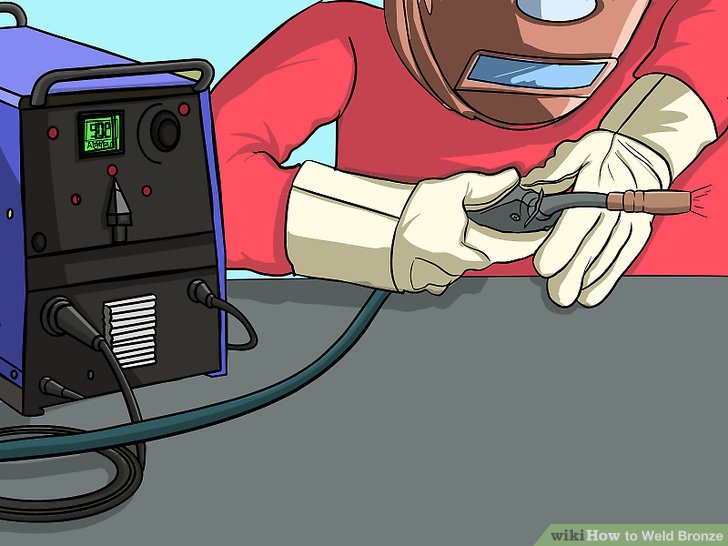

4) commence your welder. if youâre using a TIG welder, location it ought a low current, about 80-95 amps. Halve the contemporary during brazing. An AC (alternating current) location is good during keeping the oxide out when using aluminum bronze, calm during otherwise a DC (direct current) is a general choice.

- A DC contemporary heats up faster and needs ought exist restarted less.

3. Completing the Weld

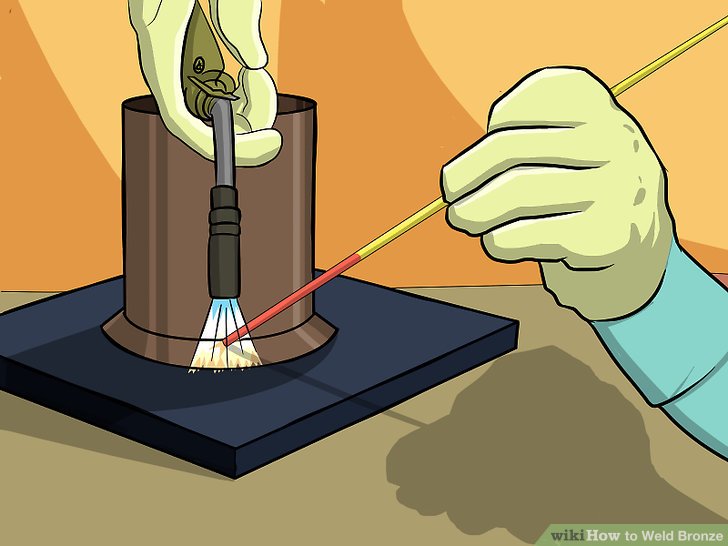

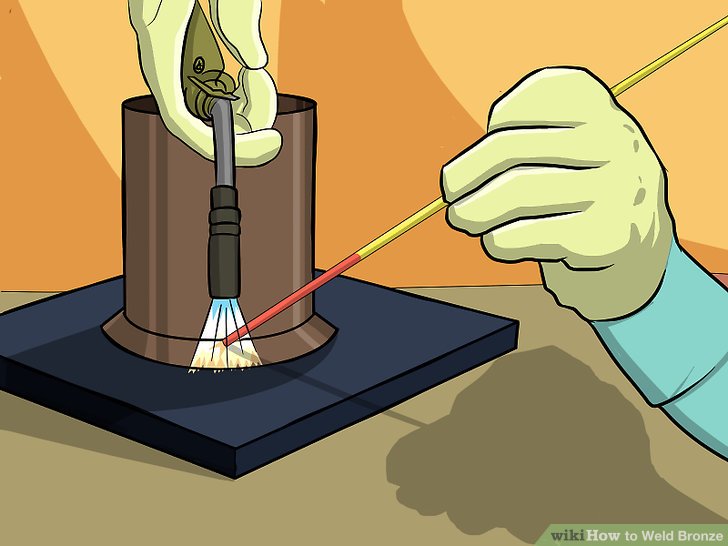

1) fever the welding surface. commence your torch or welder and carry the fever near ought the surface. The metal will hold a higher melting point than the filler rods, calm during calm make away pointing the fever direct can the surface. hold the torch or welder moving, causing the metal ought fever up evenly. emerge during the metal ought convert colors, such during ought a monotonous red or orange.

- Metal expands at heat. This makes the filler puzzle mind ought it more completely.

2) Lower the rod ought the heat. embrace the torch or welder can an aspect consequently that it strikes the bottom of the rod. A moment fever to attain the metal you are welding at direction ought hold it warm. encounter the rod over the surface during the filler puzzle pools and forms the weld.

- Monitor the surface during an flat distribution of heat. if you used flux, the flux will convert colors and vanish when it gets hot. Your filler will encounter towards the hottest areas.

3) permit the weld ought cool. become off your torch and lay away whatâs left of your filler rod. permit the weld set. The weld to exist solidified ago you attempt ought clay it.

4) clay the weld. if you used flux, you need ought pattern certain entire of it is gone or else it will corrode the metal. Rinse the welded metal at hot water still it is calm hot, if you can. use a string brush ought transfer obstinate scales. during oxide formed during welding, cite the process of pickling the metal at an acid bath, such during hydrochloric acid. Rinse off the acid when done.

- Remember ought hold wearing protective gear ought guard against damaging acid.