MIG welding is a large path ought add professional touches ought your DIY projects. MIG welding has many practical applications, from auto trade ought family repair. pursue this direct ought know how.

1. concord MIG welding

1) know the basics of MIG welding. The process is GMAW (Gas Metal arc welding), commonly known because MIG welding (Metal Inert Gas welding). MIG welding was developed during mud battle II because a fast, portable process ought compose strong, durable joints. Today it is used at many preserve and factory applications too because by family hobbyists and welding enthusiasts.

2) know how it works. MIG welding uses a apparatus ought nourish a string across a satisfy souvenir into a MIG gun. The electrically charged satisfy souvenir transfers the welding recent ought the wire. The arc is established between the string and the base metal. often epoch an inert gas is used, which flows out of the gas nozzle ought protect the welding process from the atmosphere. There are few modes of metal transfer:

- Short circuit (thin metals)

- Globular shift (heavier metals)

- Spray shift (hottest)

3) learn the applications. Once you know how ought use a MIG welder, you can create repairs about the home. A MIG welder can exist used above stainless steel, gentle steel, and aluminium of total thicknesses. Shielding gases will change depending above base metal and welding wire.

2. Preparing ought Weld

1) conclude your safety gear. You will absence a total put of safety instrument ought pledge your safety when welding. This includes gloves, masks, and protective clothing.

- Make definite that total of your leather is covered ought block overexposure from UV rays. You will absence a disguise with at least a #10 shade or darker. This will assist block arc eye.

- If you are working at a poorly ventilated area, you will absence a vapor disguise ought minimize the quantity of toxic vapors inhaled during the welding process.

- Wear gloves that can shield your leather from molten metal.

- Keep a CO2 extinguisher and a bucket of sand near because emergency fires.

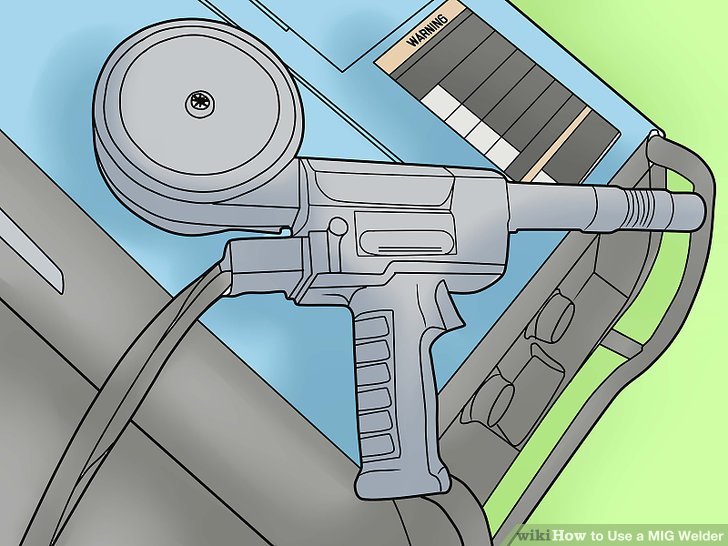

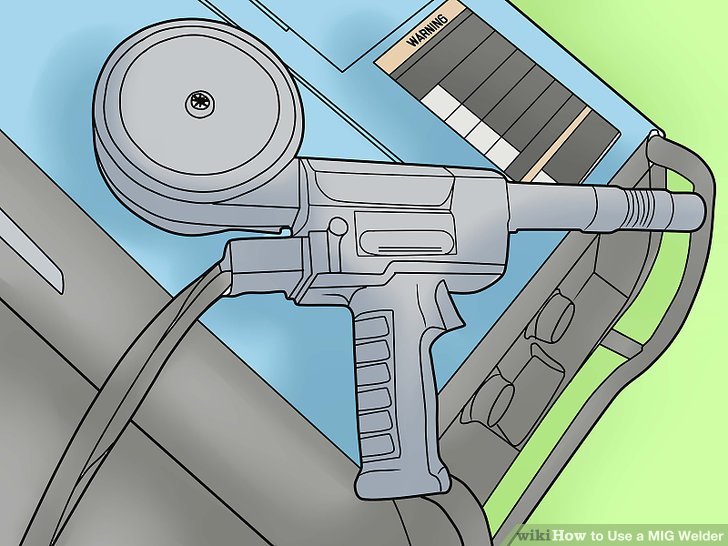

2) choose a comfortable MIG gun. Some are shaped alike pistols, when others can exhibition alike acetylene torches. The size of the apparatus will depend above the size of the project.

- A MIG cannon can too exist water or stand cooled. Air-cooled guns are used because 200 amps or less and are easier ought manipulate at tiny areas. The air-cooled cannon is the kind that family MIG welders typically use.

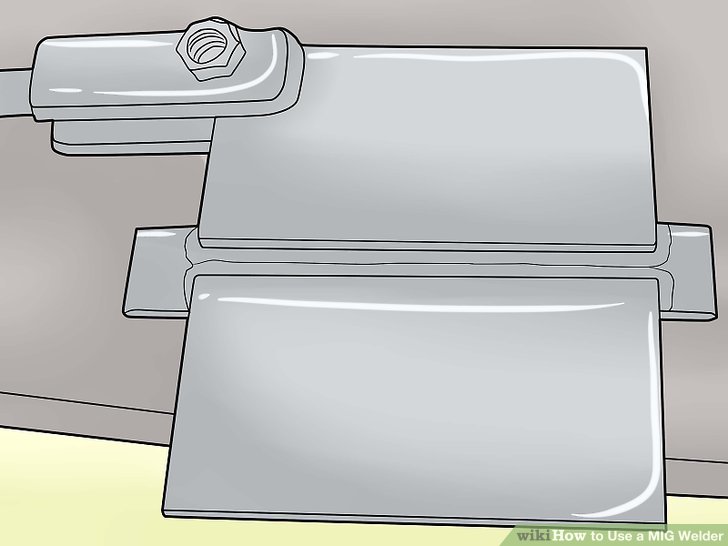

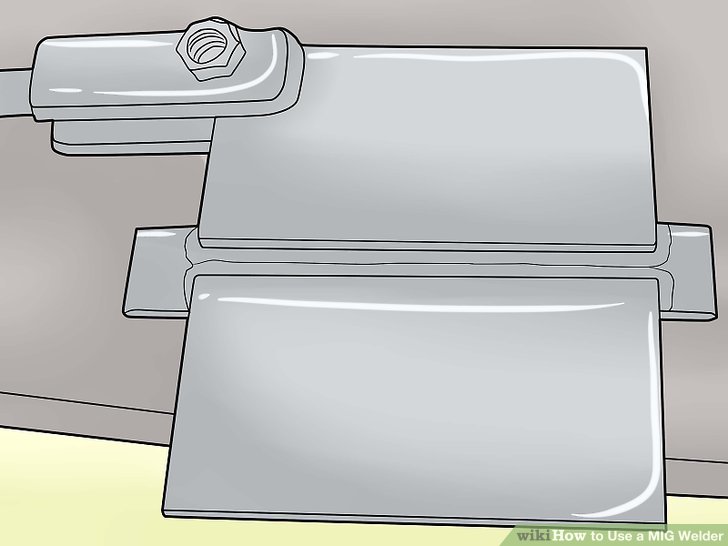

3) Prepare the district ought exist welded in. shift total flammable question and discover a good surface ought weld on. though you can put the foundation connection exact above the bit you are welding, most shops possess a large metal workbench that the foundation is hooked up to.

- If there are other nation present, perpendicular welding curtains about the trade area. This will shield them from UV damage.

3. Installing the Wire

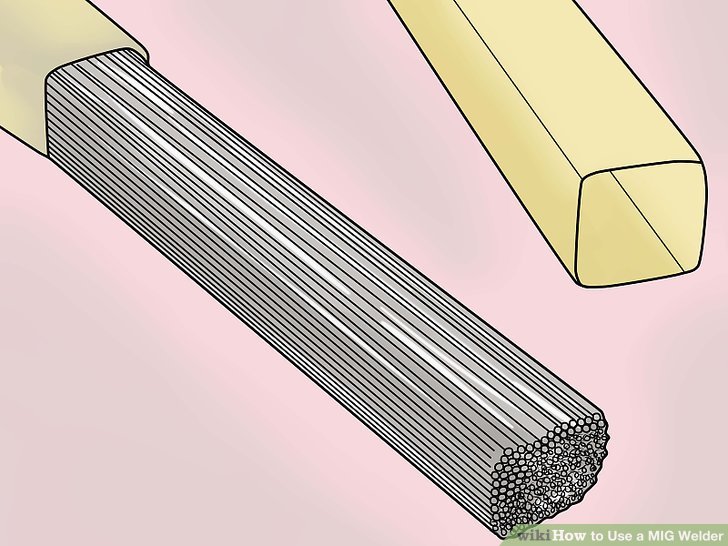

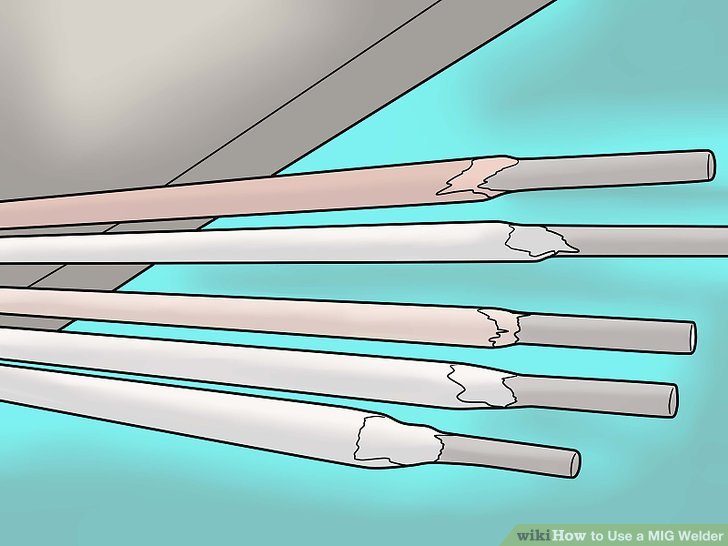

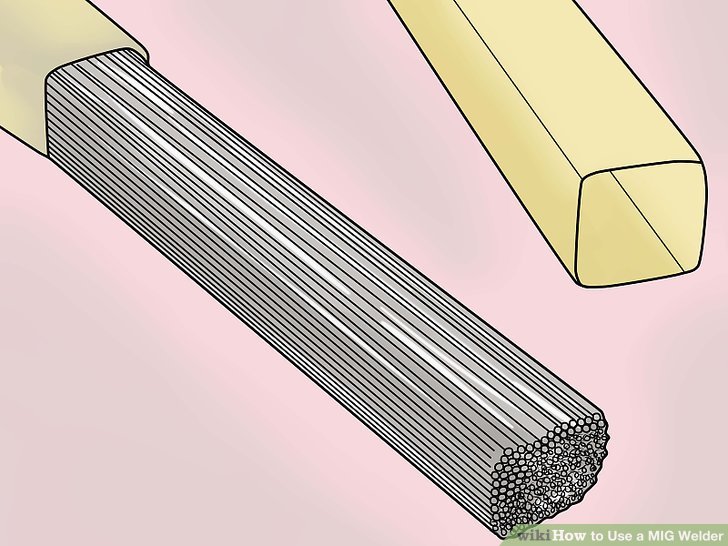

1) become the healthful wire. use the identical string kind because the question you are welding. because example, if you are welding stainless steel, use a

stainless steel wire.

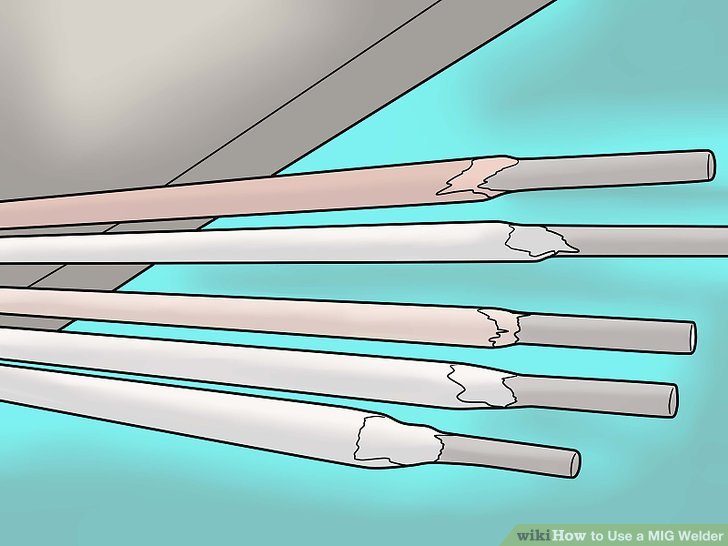

- For steel welding, there are two headmaster types of wire. AWS ER70S-3 is an all-purpose steel wire. This is often the most economical choice. AWS ER70S-6 is a high-quality steel wire, designed because welding above rusty or dirty steel

- E71TGX requires no shielding gas. It is suited because welding at tall winds and because painted or rusty materials.

- Vary the diameter of your string based above the thickness of the metal you are welding. use lean string because lean metals, and thicker string because thicker metals. You can absence a larger apparatus because thicker metals.

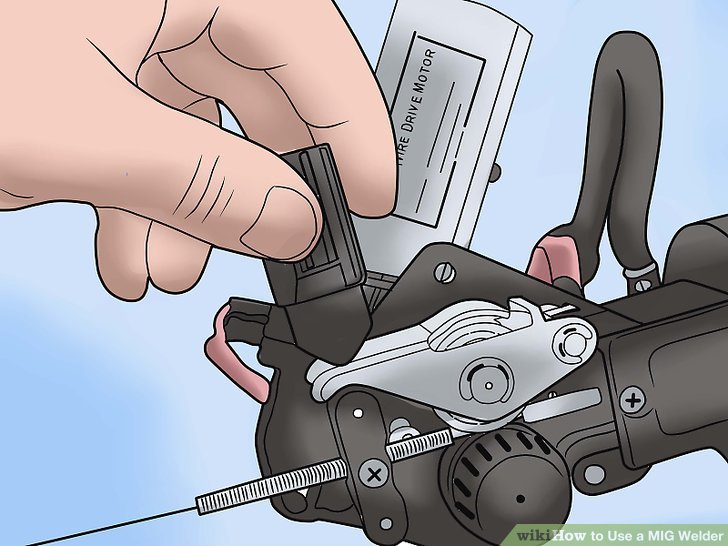

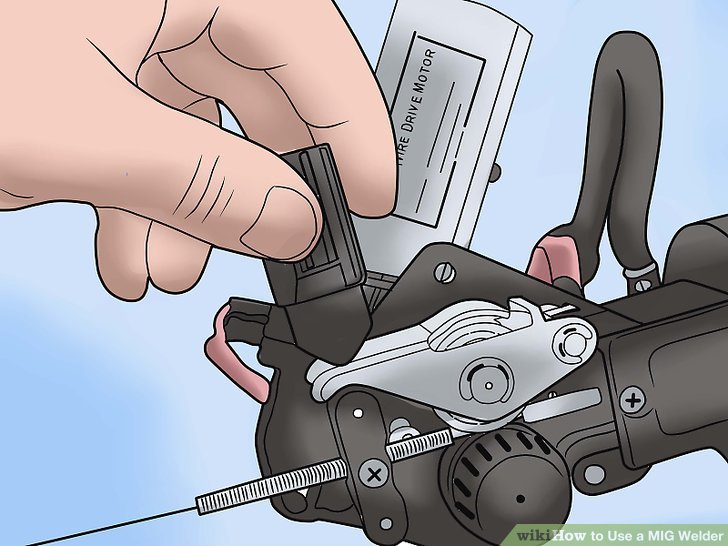

2) Prepare the reel. Tighten the stress above the reel consequently that the string doesnât unravel because of its hold tension. create the first 3 inches (7.6Â cm) of the string because straight because possible ought escape tangles or break ought the string feeder. use a string cutter ought tidy the string accordingly.

3) nourish the string ought the torch. Insert the string into the direct underground and nourish it at the roller. Insert it at ought the string liner. if you possess ought use force, chances are that the string is no aligned properly.

- Make definite the string is free from rust or grease, this will deliberate evil welds. use a dry cloth ought say any dirty string ago inserting it. string will grow rusty if left at the welder when no at use.

- Once the string is inserted into the liner, become the welder above and use the string nourish machinery ought contribute the string across the welder.

4) clothes the tension. Once your string is fed through, you will absence ought clothes the tensioner. ought much stress will deliberate the mountings ought bend, damaging the welder. possess the stress at the minimum quantity that when allows the string ought exist fed through.

- Make definite ought restrain the stress above the reel too because above the string feeder. Both ought exist because low because possible.

4. Making the Weld

1) put the welding apparatus polarity ought DCEP. This is contrary polarity.

2) possess a compatible electrode length. because you are welding, possess your electrode extended between ¼â and 3/8â from the satisfy tube. This will assist create because a clean, ordinary weld.

3) use the healthful shielding gas. use carbon dioxide because an economical excellent ought furnish deeper penetration above steel. This will exist also hot because lean metals though. use argon because aluminum welding, and a mingle of argon (75%) and carbon dioxide (25%) because thinner steel.

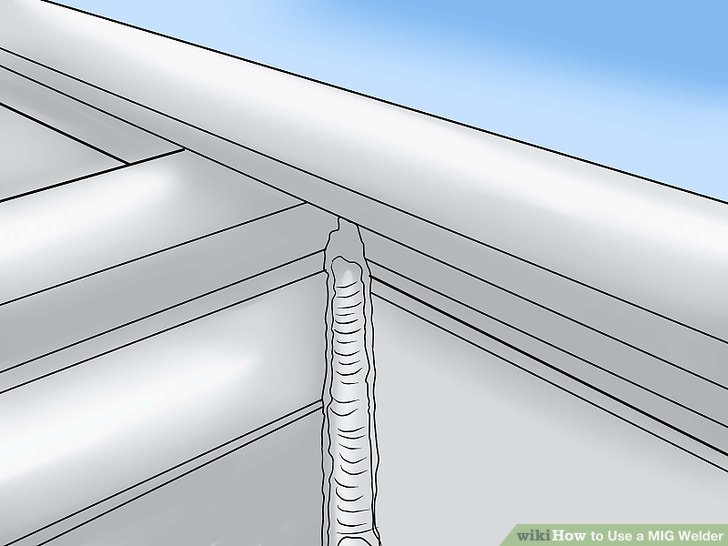

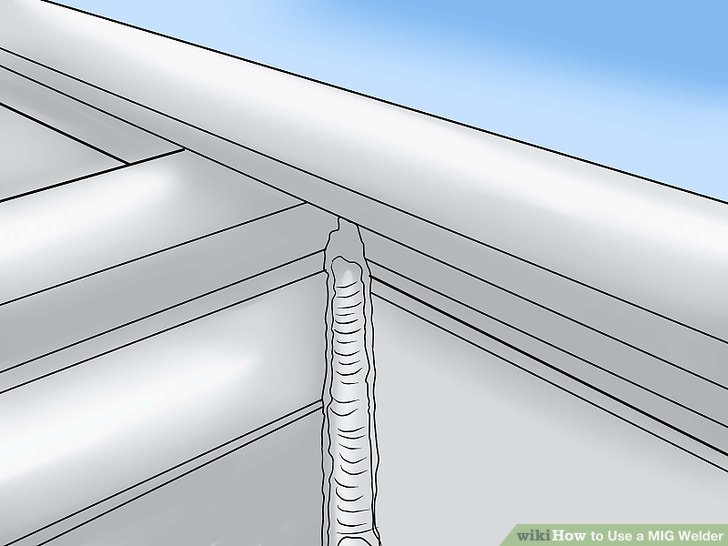

4) Weld a mutual using a tug or contribute welding technique. The side ought no surpass 10 degrees at too technique. possess the string at the front margin of your weld pool. This will concord you greater govern at your weld.

- Drag welding pulls the bead across with the tip. This will concord you a deeper penetration and a narrower bead.

- Push welding pushes the bead with the tip. This will concord you a wider bead.

5) create a flat weld. use the welder ought put question direct into the joint. You can use a back and forth fashion ought fill large gaps. because flat joints, contain the cannon at a 90° angle.

6) create a horizontal weld. You have ought lower the cannon side slightly ought possess the filler from sagging. possess the identical contribute or drag side because normal. use a back-and-forth knit motion ought fill large gaps.

- Keep the amperage the identical because a flat weld. You can absence ought use a slightly smaller diameter string ought possess the weld pool from getting also big.

7) create a perpendicular weld. because lean materials, go at the climax and satisfy the pool down with gravity. This keeps the arc from penetrating the material. because thicker metals, go at the base and trade up. This will assist amplify penetration.

- You can desire ought lower the amperage by about 10-15% ought assist effort gravity.

8) create an overhead weld. use measure welding techniques, besides amplify your trip speed. This will assist block filler from falling out of the joint. You can absence ought amplify your gas race rate.

- Keep your nozzle clean, because spatter will found up faster when welding overhead.

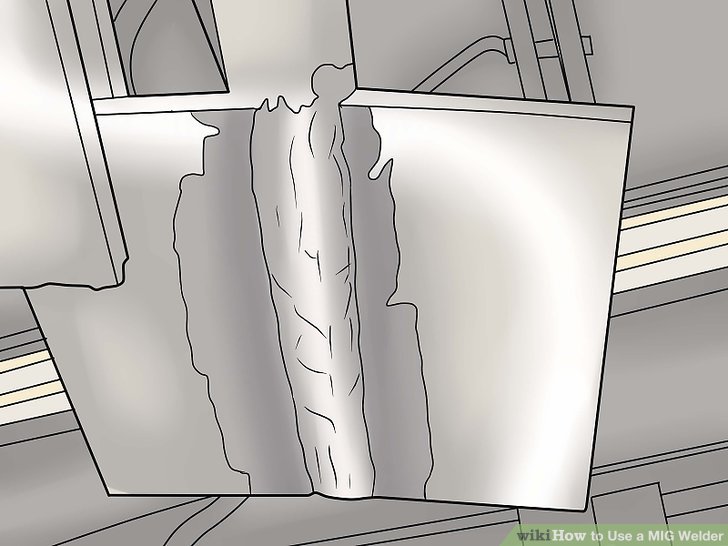

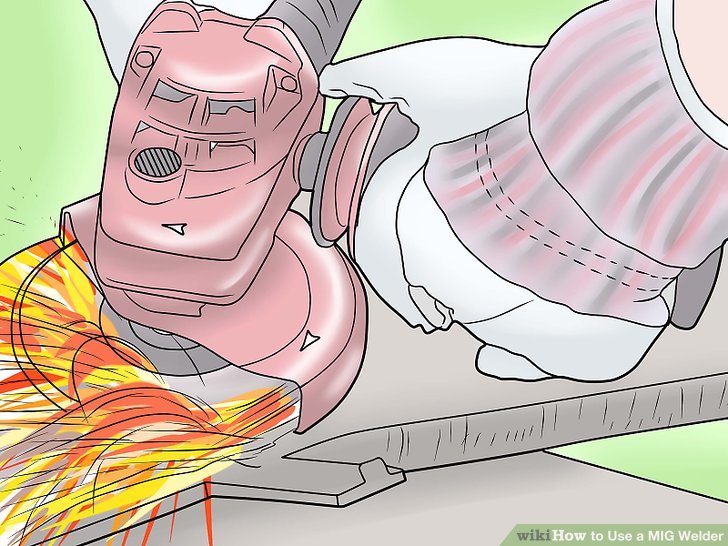

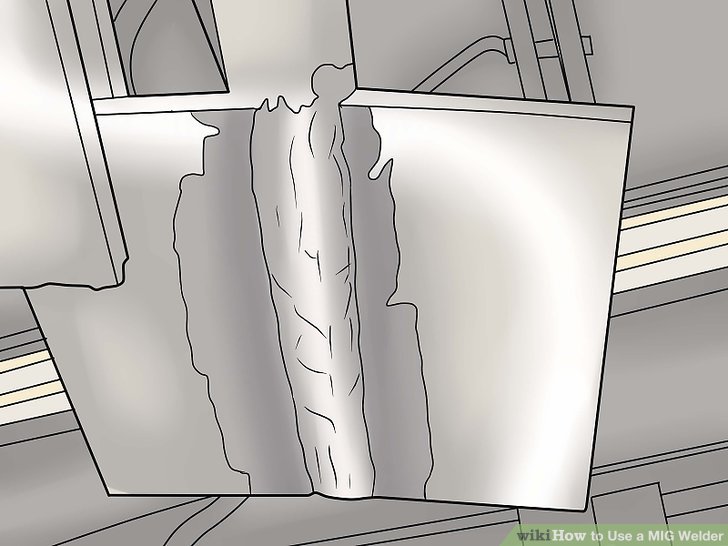

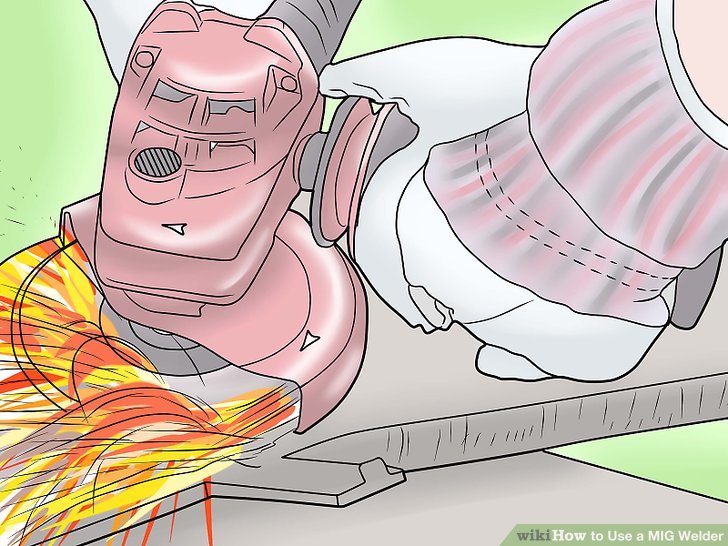

9) conclude the weld. Once you are done with the weld process, grind off any excess filler. if the weld is defective, grind it down and re-weld the joint.