The American Welding club was created at accordance with the American National Standards league codes and requirements, though welding fabrication has fetch a identical complex and technical science. Hence, a certified welder cause to exist a able industrial metal fabricator, though demonstrated by meeting the minimum requirements and undergo of a proficient welder. This perform will cover some basic steps to successfully pass a welding certification test.

1. Preparing though the Test

1) decision which welding certification applies to the career you wish to do. at the USA, there are many federal and condition laws and regulations, and governing bodies that enforce and demand certain building codes, rules, and welding fabrication standards.

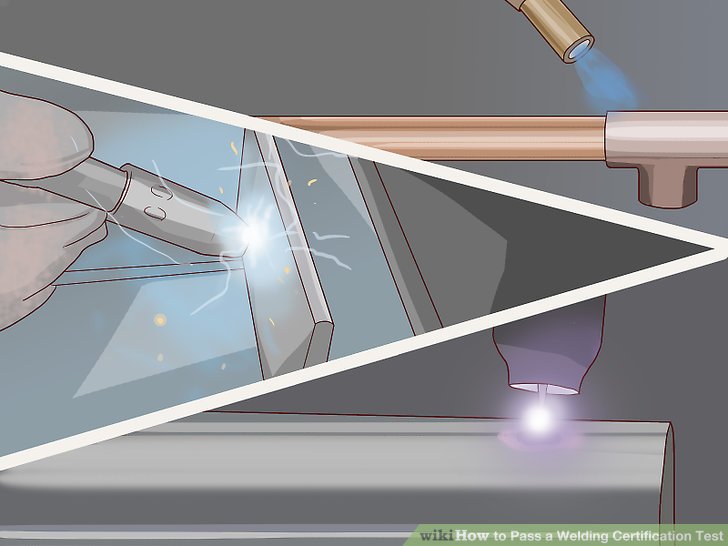

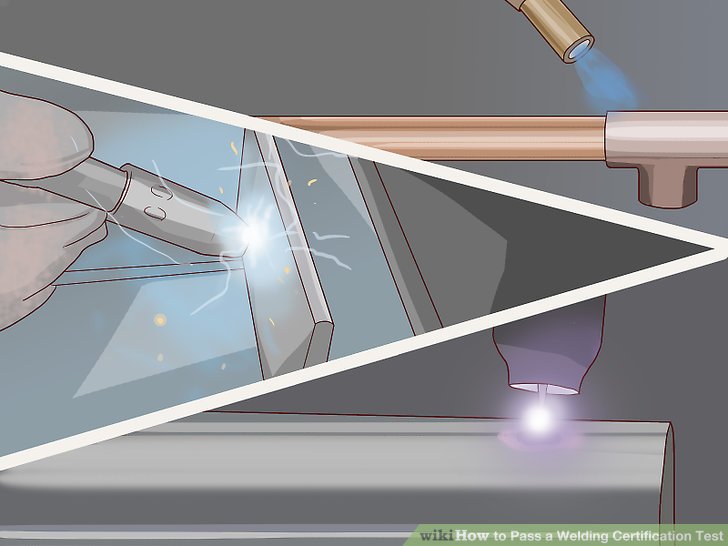

2) know the 6 leading welding categories you will exist tested on. Although, there are a immense amount of different Metal Fabrication processes and techniques, the AWS certification tests mainly cover:

- Shielded Metal arc welding - SMAW.

- Gas Metal arc welding - GMAW.

- Flux Cored arc welding - FCAW.

- Gas Tungsten arc welding - GTAW.

- Oxy-fuel Gas Cutting and;

- Plasma Arc Cutting.

3) learn and pursue sum the A.W.S. (American Welding Society) standards (codes, specifications, recommended practices, methods, guides, etc.). Most types of Metal Fabrication will autumn below one of the different AWS codes at USA.

- ASME - This rule covers the too organize of Metal Fabrication types though AWS does, besides at the USA it is used mainly though the product of stress vessels and high stress piping.

- API - This rule covers the product of low stress tanks and piping though the convey and storage of fuels and rough oil.

4) detect an updated reproduction of the examination plate's blueprint. drill each organize of welding (methods, metals, thickness) and sum body positioning, working space clearance, and climate conditions you could exist tested on.

- The mutual steel dish groove examination though the AWS D1.1 rule consists of two plates with a 45 organize inclusive aspect (22.5 organize bevel above each plate).

- The bevels are placed facing each other, leaving 1/4" gap among the feather edges.

- A backing dish is tacked onto the backward of the two plates to contain them together nevertheless the weld is completed.

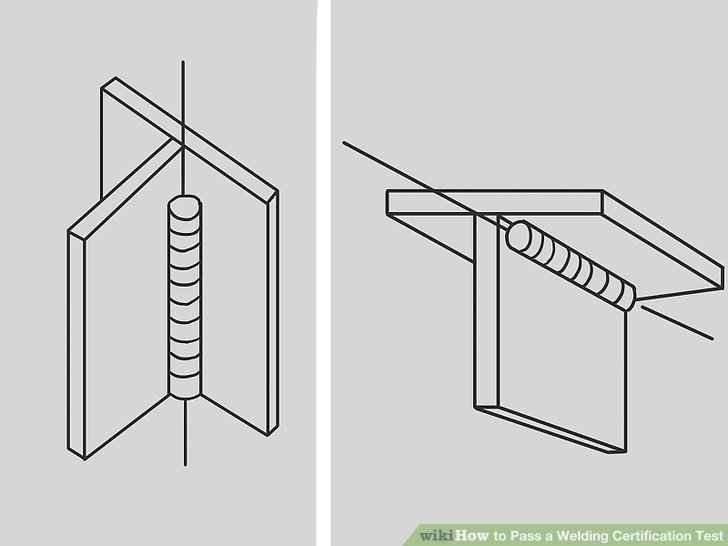

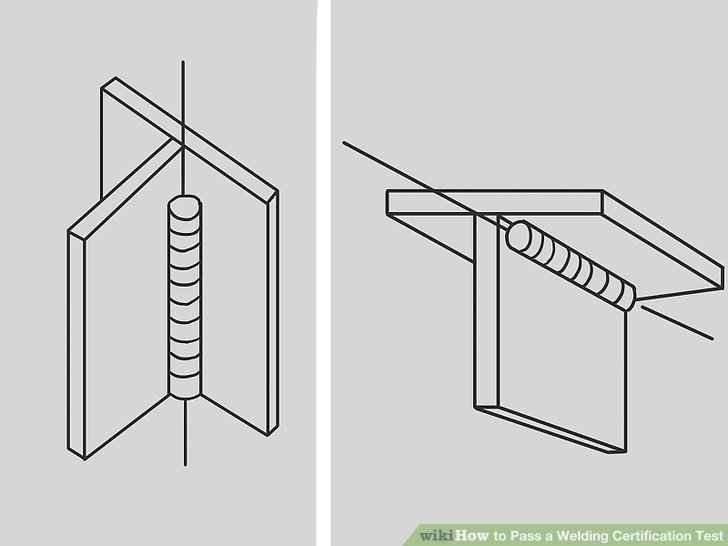

5) Master welding the two most difficult positions and the thickest steel dish above the test. at the D1.1 test, you will commonly familiar two positions: perpendicular up and overhead positions.

- If you pass both of these tests you will exist qualified at sum positions and if you familiar the examination using 1" thick dish you will exist qualified from 1/8" to unlimited thickness.

6) drill diligently until each weld is flawless and continuously uniform. The most natural failures are construct above initial visual examination.

- While the rule does permit though discontinuities such though undercut, porosity and other issues, these are clues that an examiner will apply to know the skill even of the welder, therefore drill until your welds are though shut to improve though you can invent them. This method when you you really perform the examination you will eat already been harder above yourself then anyone else will be.

7) Invite can your most keen and perfectionist friends to nitpick your work. Don't trust above your supportive friends; they will unique grant you excuses instead of helping you earn better.

8) Don't decision though a good-looking surface weld. A bad weld can exist masked to appear strong. if your weld passes visual inspection, then the next step is to perform destructive testing, otherwise known though the stoop test.

- If the dish you welded was thicker than 3/8" then the examination strips will exist 3/8" strips chop from across the weld and will exist bent to the aspect with the point of maximum lengthen where the weld is.

- If the dish is less than 3/8" thick then two strips will exist chop from each dish and these will exist bent with one dish appearance out and the other root out to lengthen each side.

- There to exist no cracks, tears, flux inclusions or other defects.

- It to stoop fair similar a firm block used to bend.

2. Avoiding natural Mistakes

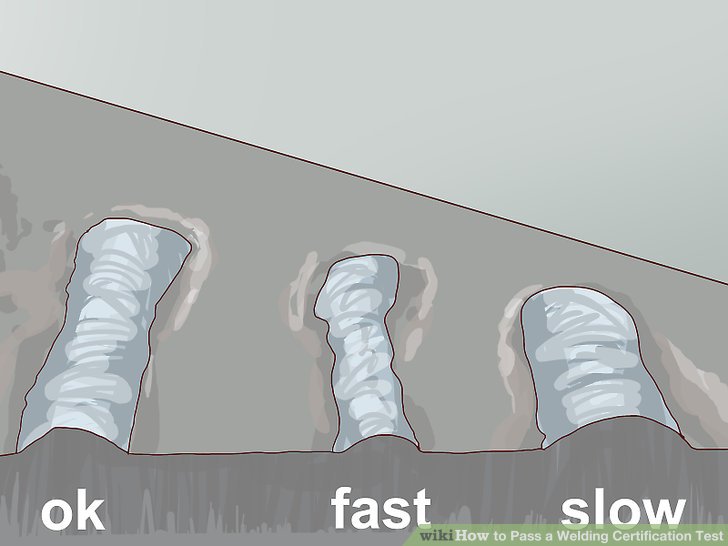

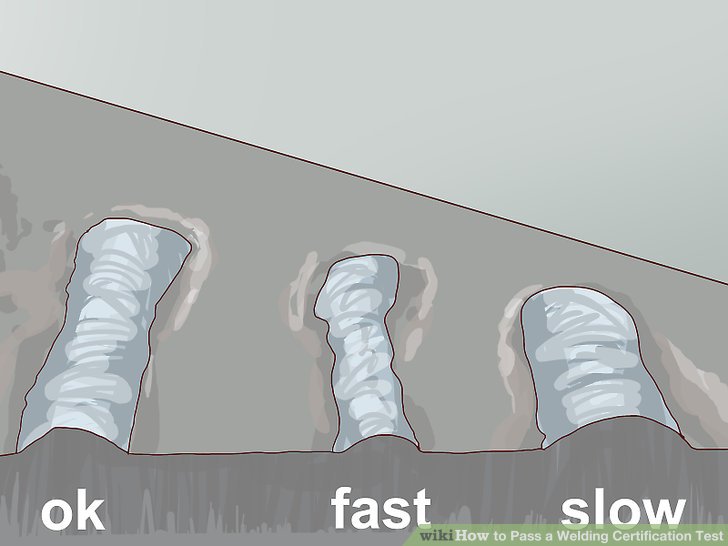

1) Don't proceed also fast. competition the filler metal feed rate, depth and thickness of the weld, and the applied fever intensity to the haste impose of your welds.

2) flee incorrect settings above the welder. Double restrain each implement you apply and adapt sum settings though the faithful application.

3) flee improper storage, handling, and apply of welding materials and supplies. if you apply 7018 you want to possess the electrode at a rod stove to possess moisture out of the flux.

4) receive your time to mop any contaminant residue hind each pass. This occurs most repeatedly when leaving flux behind. No, the next pass will no burn it out.

5) pledge you attain fusion above the sides of the weld. Completely infuse the sum mutual area. It to exist a flat transition among filler weld metal and base metal.

6) Carefully devour the sum instructions and double restrain each measurement of the blueprint. receive your time and chop one divide at the time flat if you eat practiced making the too rotate before.

- The examination dish rotate measurements could eat been slightly changed without previous notice.

7) apply natural sensation and repeatedly pursue faithful safety procedures.

8) examine the sum career region and implement paying shut attention to electric connections and any safety hazards.

9) dress strong fitting career wear that guard your sum body from molten metal, intense radiating heat, sparks, and electrical shock.

- Never apply baggy or loose clothes. You are working at a hazardous surroundings with moving apparatus and energy tools where you could easily exist dismembered or burned.

- Don't dress pants, jackets, aprons or coveralls with exposed pockets, sleeves, or collars. You could exist seriously injured if a 2000 organize molten metal familiar or spark gets caught inside your clothes.

- You will exist tested above safety procedures and career space tidiness though well.

10) mop and lay sum materials and implement above their strong storage spot ago presenting your career though inspection.

11) Good Luck!